17+ Stylish Concrete Floor Ideas for Your Home

stylish concrete floor ideas ,Concrete floors have evolved far beyond their utilitarian industrial origins to become sought-after design elements that combine durability with striking aesthetics. Once relegated to basements and garages, concrete flooring now graces living rooms, kitchens, bedrooms, and commercial spaces where its versatility and low maintenance appeal to modern homeowners. The transformation of plain concrete into stunning floor surfaces requires understanding various finishing techniques, color options, and protective treatments that unlock this material’s full potential.

The growing popularity of concrete floors stems from multiple advantages they offer over traditional flooring materials. Concrete withstands heavy traffic, resists moisture damage, accommodates radiant heating systems efficiently, and requires minimal upkeep compared to wood or carpet. Beyond these practical benefits, concrete floors provide blank canvases for creative expression through staining, polishing, stamping, and various decorative treatments. Whether your design preferences lean toward sleek minimalism, warm industrial charm, or colorful artistic statements, concrete flooring adapts to realize your vision while delivering performance that lasts for decades.

Polished Concrete with High Gloss Finish

Polished concrete represents the pinnacle of contemporary flooring sophistication, offering mirror-like surfaces that reflect light and create spacious feelings in any room. This finish results from mechanically grinding concrete surfaces with progressively finer diamond abrasives, followed by chemical densifiers that harden the concrete and specialized polishing pads that achieve desired sheen levels. The process exposes aggregate beneath the surface cement paste, creating subtle visual texture and depth.

The degree of polish ranges from satin to high gloss, each creating different aesthetic effects. High gloss finishes maximize light reflection, making spaces feel larger and brighter, while satin finishes provide sophistication without overwhelming shine. Polished concrete works exceptionally well in modern and minimalist interiors where clean lines and uncluttered spaces take priority. The reflective quality enhances natural and artificial lighting, reducing energy costs in commercial applications.

Maintenance of polished concrete proves remarkably simple. Regular dust mopping and occasional damp cleaning with pH-neutral cleaners maintain the finish indefinitely. Unlike waxed floors requiring periodic stripping and reapplication, polished concrete maintains its appearance for years without intensive care. The hardened surface resists staining, scratching, and wear better than most flooring options, making it ideal for high-traffic residential and commercial environments.

Acid-Stained Concrete Floors

Acid staining creates rich, variegated color effects that resemble natural stone, marble, or aged patina. This chemical process involves applying acidic solutions containing metallic salts that react with minerals in the concrete, producing permanent color changes that penetrate the surface rather than coating it. The resulting colors appear organic and irregular, with subtle variations that add character and visual interest impossible to achieve with uniform coatings.

Available colors tend toward earth tones including various browns, tans, terracottas, blues, and greens, though the final appearance depends on concrete composition, age, and application technique. The translucent nature of acid stains allows underlying concrete variations to show through, creating unique one-of-a-kind floors where no two installations look identical. This organic quality suits transitional, rustic, and Mediterranean design styles particularly well.

Application requires careful surface preparation including thorough cleaning and pH neutralization. Contractors apply acid stain, allowing it to react for several hours before neutralizing and rinsing. Multiple stain colors can be layered or applied in patterns to create custom effects. After staining and complete drying, protective sealers preserve the color while providing stain and moisture resistance. The combination of chemical artistry and protective finishing creates floors with depth and character that improve with age.

Water-Based Stained Concrete

Water-based concrete stains offer broader color palettes and more predictable results than acid stains while maintaining an eco-friendlier profile. These stains work by penetrating concrete pores with pigment particles suspended in water-based carriers, creating semi-transparent color that allows some concrete texture to remain visible. The color range includes vibrant blues, greens, reds, yellows, and purples alongside neutrals, enabling design schemes impossible with acid stains alone.

Unlike reactive acid stains that create organic variations, water-based stains provide more uniform color coverage, making them ideal for modern interiors requiring consistent appearance. Multiple coats build color intensity, allowing precise control over final saturation. Stains can be applied solid for uniform fields of color or diluted and layered to create custom shades and subtle gradients .https://casolia.com/how-to-do-concrete-floors-ideas/

Water-based stains work on both interior and exterior concrete and prove particularly valuable for refreshing existing concrete floors without extensive surface preparation. They bond mechanically rather than chemically, so proper surface porosity ensures good adhesion. This staining method suits contemporary, eclectic, and artistic interiors where bold color choices enhance overall design schemes. Sealing remains essential to protect the stain and underlying concrete from wear and staining.

Stamped Concrete Patterns

Stamped concrete replicates the appearance of stone, brick, tile, or wood through textured mats pressed into freshly poured or overlay concrete. This technique delivers high-end aesthetics at a fraction of the cost of actual stone or wood flooring. Hundreds of stamp patterns exist, ranging from realistic slate and flagstone impressions to geometric tile designs and rustic cobblestone textures.

The stamping process begins with pouring and leveling concrete to proper thickness. Color hardeners or integral pigments add base color, while release agents in contrasting tones create antiquing effects in recessed pattern areas. Textured stamps are pressed into the surface while concrete remains workable, creating three-dimensional patterns. After initial curing, surfaces are cleaned, sealed, and sometimes enhanced with additional antiquing stains that emphasize texture depth.

Stamped concrete works for both indoor and outdoor applications including patios, walkways, pool decks, and interior floors. The technique proves particularly popular in living rooms, entryways, and kitchens where the appearance of natural materials is desired without associated maintenance challenges. Modern installation methods and sealing technologies have made stamped concrete increasingly durable and realistic, fooling many observers into believing they’re seeing actual stone or tile.

Epoxy Coating Systems

Epoxy coatings transform concrete floors with thick, durable layers that provide both protection and decoration. These two-part systems consisting of resin and hardener chemically bond to concrete, creating seamless surfaces resistant to chemicals, stains, impacts, and moisture. Epoxy floors suit garages, workshops, basements, commercial kitchens, and increasingly, residential living spaces where durability meets design.

Solid color epoxy creates uniform, glossy surfaces in virtually any color imaginable. Metallic epoxy systems incorporate reflective pigments that create swirling, three-dimensional effects resembling liquid metal, marble, or ocean waves. Decorative flake systems involve broadcasting colored vinyl chips into wet epoxy, creating speckled terrazzo-like appearances available in countless color combinations. Each system offers different aesthetic and performance characteristics.

Professional installation ensures proper surface preparation including grinding to open concrete pores and removing contaminants that prevent adhesion. Multiple epoxy layers build thickness and durability, with final clear topcoats providing UV protection and enhanced gloss. The resulting floors prove exceptionally easy to clean and maintain while withstanding heavy use. Epoxy’s design flexibility makes it suitable for modern, industrial, and contemporary interiors where bold flooring statements enhance overall design impact.

Exposed Aggregate Concrete

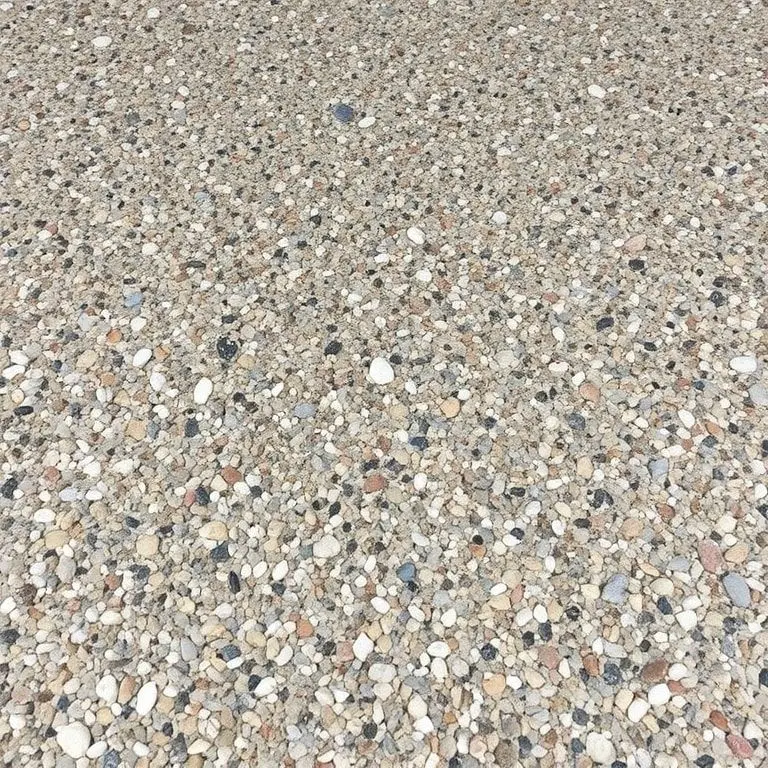

Exposed aggregate finishes reveal the decorative stones and pebbles within concrete mixes, creating textured surfaces with natural beauty and excellent slip resistance. This technique involves removing the surface cement paste after concrete has partially cured, leaving embedded aggregate visible and slightly raised. The result resembles terrazzo but at significantly lower cost, with organic character that suits both modern and traditional design schemes.

Aggregate selection dramatically impacts final appearance. Small pea gravel creates fine, uniform texture while larger river rocks produce bold, dramatic effects. Colored aggregates in glass, quartz, or specialty stones add vibrant accents. Some installations incorporate shells, recycled glass, or semi-precious stones for unique custom effects. The variety of aggregate options allows designers to create floors perfectly coordinated with overall interior palettes.

Creating exposed aggregate floors requires careful timing. After pouring and initial setting, surface retarders slow cement curing at the top while underlying concrete hardens. Workers then wash and brush away surface paste, revealing aggregate beneath. Alternative methods involve grinding and polishing to expose aggregate in existing concrete slabs. Proper sealing protects the surface while enhancing aggregate colors and providing stain resistance. These floors work beautifully in entryways, patios, pool surrounds, and commercial spaces requiring durable, attractive flooring.

Concrete Overlay Systems

Overlays provide opportunities to transform existing damaged or outdated concrete floors without removal and replacement. These thin toppings bond to existing substrates, creating fresh surfaces ready for decorative treatments. Overlay thickness ranges from feather-edge applications measuring mere millimeters to half-inch or thicker systems that can be stamped or textured like new concrete.

Self-leveling overlays create smooth, uniform surfaces ideal for polishing or coating with epoxy and stains. Stampable overlays accept texture patterns just like fresh concrete, enabling complete floor redesign without demolition costs. Micro-toppings provide extremely thin applications for subtle texture or as bases for decorative finishes. Each overlay type serves different purposes and aesthetic goals.

The overlay process begins with thorough surface preparation including cleaning, repairing cracks, and profile grinding to ensure mechanical bonding. Primer coats enhance adhesion before overlay material is mixed and applied. Decorative treatments follow based on desired final appearance. Overlays solve numerous flooring problems including surface damage, staining, or simply outdated appearance, making them cost-effective renovation solutions. They work in virtually any interior space and suit modern, industrial, and eclectic design styles.

Metallic Epoxy Floor Designs

Metallic epoxy systems create jaw-dropping three-dimensional effects that resemble liquid metal, gemstones, or swirling clouds. These specialized coatings incorporate metallic pigments that shift and move during application and curing, producing organic patterns with incredible depth. No two metallic floors look identical, ensuring truly custom results that serve as artistic focal points.

Color options span the spectrum from subtle silvers and coppers to bold blues, greens, purples, and golds. Multiple metallic colors can be combined in single installations, creating custom effects limited only by imagination. The reflective pigments catch and play with light, making floors appear to shift and change throughout the day as lighting conditions vary. This dynamic quality adds drama and sophistication to contemporary interiors.

Application requires skilled techniques including strategic pigment placement and specialized tools that manipulate the metallic material as it cures. Contractors may use air blowers, brushes, or rollers to create specific effects like waves, veining, or cloud formations. Multiple clear epoxy topcoats protect the decorative layer while enhancing gloss and depth. Metallic epoxy suits high-end residential spaces, retail environments, restaurants, and anywhere dramatic flooring makes strong design statements.

Stenciled and Painted Concrete Designs

Stencils enable intricate patterns and designs on concrete floors without expensive stamping equipment. From geometric tile patterns to ornate medallions and borders, stenciled designs transform plain concrete into custom artistic expressions. This technique combines well with staining and painting, allowing multi-color designs with precise edges and consistent repeating patterns.

Creating stenciled floors begins with thoroughly cleaned and prepared concrete. Base colors are applied through staining or painting as needed. Stencils are positioned and secured, then contrasting colors are applied within stencil openings using brushes, rollers, or sprayers. Multiple stencils and colors build complex designs layer by layer. The process requires patience but delivers professional results accessible to DIY enthusiasts.

Stenciled floors suit eclectic, bohemian, Mediterranean, and traditional design styles where pattern and ornament enhance rather than compete with furnishings and architecture. Consider stenciling for entryways, dining rooms, or as accent borders within larger spaces. Protective sealers preserve painted and stenciled designs while providing necessary moisture and stain resistance. This approach allows frequent design updates by simply repainting and stenciling new patterns as tastes evolve.

Concrete Floor Scoring and Inlay

Scoring creates permanent decorative lines in concrete through sawing shallow grooves that define patterns, borders, or design elements. These grooves can remain natural concrete color, be filled with contrasting grout or epoxy, or enhanced with stains for definition. Scoring works beautifully to create tile-like grids, define room zones, or add geometric interest to large concrete expanses.

Simple grid patterns transform plain concrete into faux tile flooring at minimal cost. Diagonal scoring creates dynamic visual movement, while random patterns suggest natural stone. Curved scoring requires specialized equipment but enables organic flowing designs. The depth and width of scored lines can be varied for different effects, from subtle definition to bold graphic statements.

Inlay techniques take scoring further by routing deeper grooves then filling them with contrasting materials such as colored epoxy, metal strips, wood, or decorative aggregates. These inlays create permanent artwork within floors, allowing logos, borders, or custom designs. The combination of scoring and inlay suits modern and contemporary interiors where graphic floor elements enhance minimalist furnishings and clean architectural lines.

Rustic Concrete with Distressed Finish

Intentionally distressed concrete creates aged, weathered appearances that suit industrial lofts, rustic homes, and spaces embracing wabi-sabi aesthetics. Distressing techniques include chemical etching, mechanical abrasion, surface burning, and strategic staining that mimics years of wear. The resulting floors look authentically old rather than freshly installed, with character and imperfections that add warmth to concrete’s inherent coolness.

Creating distressed concrete involves multiple layered techniques. Acid etching removes surface paste irregularly, revealing aggregate in random patterns. Grinding creates wear patterns focused on high-traffic areas. Multiple stain colors applied and partially removed mimic oil stains, water marks, and natural aging. Some contractors add deliberate cracks or chips for enhanced authenticity, though structural integrity remains uncompromised.

This finish particularly suits converted industrial spaces, farmhouse interiors, and eclectic homes where imperfection equals character. The casual, lived-in quality softens concrete’s modern associations, making it compatible with vintage furnishings and rustic decor. Sealing remains important but matte or low-gloss finishes maintain the aged aesthetic better than high-gloss products that appear too new and pristine.

Colored Integral Concrete

Integral color involves adding pigments directly to concrete mix before pouring, creating color throughout the material’s depth rather than just at the surface. This approach ensures color consistency even if the floor chips or wears, and provides more uniform appearance than topical stains. Available in earth tones plus blues, greens, grays, and even blacks, integral color suits modern minimalist and industrial design schemes.

The intensity of color depends on pigment loading, with higher concentrations producing more saturated hues. Light colors require less pigment and prove more economical, while achieving true blacks or deep colors requires significant pigment quantities. Integral color can be combined with other decorative techniques including polishing, stamping, or staining for enhanced visual interest and depth.

Installation requires careful batching to ensure color consistency across the entire floor, particularly important for large installations requiring multiple concrete loads. Professional contractors maintain strict quality control over mixing to prevent color variations. Once cured and sealed, integrally colored concrete provides permanent color that never wears away, peels, or requires touch-ups. This makes it ideal for high-traffic commercial and residential applications where long-term appearance matters.

Concrete Floors with Radiant Heating

Concrete’s excellent thermal mass makes it ideal for radiant floor heating systems that provide efficient, comfortable warmth. Hydronic or electric heating elements are embedded within or beneath concrete slabs, turning floors into gentle radiators that warm spaces evenly without forced air systems. The combination of beautiful concrete finishes with radiant heat creates comfortable, energy-efficient homes.

Polished, stained, or any decorative concrete finish works with radiant heating, though installation sequencing becomes critical. Heating elements must be properly positioned and tested before final concrete pours or overlay applications. Concrete thickness affects heating response time, with thinner applications heating faster but storing less thermal energy. Professional installation ensures heating systems operate efficiently without damaging decorative floor finishes.

Radiant heated concrete floors prove particularly valuable in bathrooms, kitchens, and living areas where comfort matters most. The warm floors eliminate cold shock common with unheated concrete and tile, making barefoot comfort possible throughout winter. Energy costs often decrease compared to forced air heating, as lower thermostat settings maintain comfort when warmth radiates from below. This combination of beauty, durability, and comfort explains the growing popularity of heated concrete floors.

Terrazzo-Style Concrete Floors

Modern concrete techniques replicate traditional terrazzo’s elegant appearance at significantly reduced cost. By incorporating colored aggregates, glass chips, or decorative elements into concrete mixes or toppings, then grinding and polishing surfaces, contractors create floors resembling classic terrazzo. The process delivers similar aesthetic impact with faster installation and lower material costs.

Creating terrazzo-style concrete involves selecting aggregate materials that complement overall design schemes. Recycled glass adds sustainable credentials alongside vibrant color. Mother of pearl chips create iridescent effects. Brass or copper divider strips separate color fields and add metallic accents. The combinations prove nearly limitless, enabling custom floors coordinated perfectly with interior palettes.

After initial curing, floors are ground progressively finer to expose aggregate and create smooth, level surfaces. Polishing brings out aggregate colors and creates desired sheen levels. Grout filling may be necessary to fill voids, followed by additional grinding and polishing. The completed floors provide all the elegance of traditional terrazzo while leveraging modern concrete technology for enhanced performance and value.

Industrial-Style Concrete with Minimal Treatment

Embracing concrete’s raw character creates authentic industrial aesthetics popular in urban lofts, modern offices, and contemporary homes. These floors receive minimal decorative treatment beyond necessary sealing, allowing concrete’s natural gray tones, subtle variations, and inherent texture to dominate. The result feels honest and unpretentious, celebrating material rather than disguising it.

Minimal treatment doesn’t mean no treatment. Proper cleaning, crack repair, and sealing remain essential for protection and longevity. Clear sealers preserve concrete’s natural appearance while providing moisture and stain resistance. Some installations include light grinding to smooth surfaces without full polishing, maintaining somewhat raw character while improving walkability and cleanability.

This approach suits minimalist, Scandinavian, and industrial design styles where restraint and material honesty take priority. The neutral gray provides versatile backgrounds for bold furnishings and artwork without competing for attention. Lower installation costs compared to elaborate decorative treatments appeal to budget-conscious renovators. Despite simplicity, properly sealed industrial concrete delivers the same durability and low maintenance as more decorated options.

Concrete Microtopping Applications

Microtoppings represent ultra-thin overlays applied at just a few millimeters thick, providing new surfaces over existing floors with minimal height increase. These polymer-modified cement-based products bond tenaciously to substrates while accepting numerous decorative treatments including staining, polishing, stamping, and texturing. Microtoppings solve flooring problems in situations where thickness limitations prevent traditional overlays.

The thin application makes microtoppings ideal for renovations where door clearances, appliance heights, or transitions to adjacent rooms limit floor build-up. Despite minimal thickness, properly installed microtoppings prove remarkably durable, resisting abrasion, staining, and moisture. They work over concrete, tile, terrazzo, and even wood substrates when properly prepared.

Decorative possibilities mirror those available with thicker systems. Staining creates color variation and depth. Light texturing provides subtle interest. Some microtoppings can even accept light stamping for texture without significant pattern depth. The versatility and problem-solving capabilities of microtoppings have made them increasingly popular for residential and commercial renovation projects where complete floor replacement proves impractical or unnecessary.

Stained Concrete with Layered Colors

Layering multiple stain colors creates complex, artistic floors with depth impossible to achieve through single applications. This technique involves applying one stain color, allowing it to react and cure, then adding additional colors in strategic patterns or overall washes. The translucent nature of concrete stains allows underlayers to influence final appearance, creating rich, sophisticated color fields.

Artists use various application methods including spraying, sponging, brushing, and ragging to place colors precisely or create organic blending. Masking with tape or stencils enables sharp color transitions and geometric patterns. Some installations incorporate six or more stain colors, each contributing subtle influence to the final palette. The process demands artistic sensibility and technical skill but delivers truly custom floors.

Layered stain applications suit high-end residential interiors, boutique retail spaces, restaurants, and anywhere floors should make artistic statements. The technique works particularly well in open floor plans where large concrete expanses benefit from color variation that defines zones without walls. Protective sealing becomes especially important to preserve the complex color work underneath.

Creating Lasting Concrete Floor Beauty

Stylish concrete floors combine practical advantages with aesthetic versatility that few materials match. Whether you choose highly polished surfaces that reflect contemporary sophistication, acid-stained floors suggesting aged elegance, or bold epoxy coatings making dramatic statements, concrete adapts to realize diverse design visions. The permanence and durability inherent in properly finished concrete ensure your flooring investment delivers beauty and performance for decades with minimal maintenance.

Success with concrete floors depends on understanding the relationship between surface preparation, decorative techniques, and protective sealing. Each finish type requires specific installation procedures and maintenance approaches. Working with experienced contractors familiar with decorative concrete ensures technical execution matches creative vision. For existing concrete floors, overlay systems provide opportunities to achieve beautiful new surfaces without the expense and disruption of complete removal and replacement.

The techniques described represent starting points for exploration rather than exhaustive options. Concrete’s versatility continues expanding as new products, application methods, and creative combinations emerge. Consider your home’s overall design direction, functional requirements, budget parameters, and maintenance preferences when selecting concrete floor treatments. With proper planning and execution, concrete floors transform from purely functional surfaces into integral design elements that enhance your living spaces while providing the reliability and longevity that make concrete such an enduring building material.

Frequently Asked Questions:

Are concrete floors cold and uncomfortable to walk on barefoot?

Concrete floors feel cool in warm weather, which many find pleasant, but can feel cold in winter without radiant heating. Installing hydronic or electric radiant heating systems addresses this concern completely, turning floors into gentle heat sources. Area rugs in seating areas also provide warm surfaces for bare feet. The thermal mass of concrete actually helps moderate indoor temperatures year-round when properly utilized.

How much do decorative concrete floors typically cost compared to other flooring options?

Basic polished or stained concrete costs between three and eight dollars per square foot installed, competitive with mid-range tile and less than hardwood. Elaborate decorative treatments including metallic epoxy or extensive stamping can reach fifteen to twenty-five dollars per square foot. However, concrete’s longevity and minimal maintenance often make it more economical than alternatives over the floor’s lifetime. Utilizing existing concrete slabs reduces costs significantly compared to new pours.

Can concrete floors be installed in any room of the house?

Yes, concrete floors work in virtually any interior space including living rooms, bedrooms, kitchens, bathrooms, and basements. Proper sealing makes them moisture-resistant for bathrooms and kitchens. They accommodate radiant heating for bedroom comfort. The key is ensuring adequate structural support, as concrete weighs significantly more than most flooring materials. Ground-level installations or renovations of existing concrete slabs face fewer structural limitations than upper-floor applications.

How do I maintain and clean decorative concrete floors?

Regular dust mopping or vacuuming removes dirt and debris that could scratch surfaces. Damp mopping with pH-neutral cleaners handles routine cleaning without damaging sealers. Avoid acidic or harsh alkaline cleaners that degrade protective sealers. Reseal floors every two to five years depending on traffic and sealer type to maintain protection and appearance. Promptly clean spills to prevent potential staining. Overall, concrete requires less maintenance than most flooring alternatives.

Will concrete floors crack over time and how can this be prevented?

All concrete may develop hairline cracks due to settling, temperature changes, or improper installation. Proper subgrade preparation, adequate concrete thickness, reinforcement with rebar or wire mesh, and control joints minimize cracking risk. Many decorative techniques like acid staining actually make minor cracks less noticeable as they blend into color variations. Overlay systems can address existing cracks. While perfection cannot be guaranteed, proper installation dramatically reduces problematic cracking.