15+ Creative Polymer Clay Extruder Ideas

The polymer clay extruder ideas stands as one of the most versatile tools in any clay artist’s arsenal. This cylindrical device transforms solid blocks of polymer clay into uniform strings, ropes, and decorative elements with remarkable consistency. Whether you are just beginning your polymer clay journey or have years of experience under your belt, understanding the full potential of your extruder can revolutionize your creative output and streamline your workflow.

Many artists purchase an extruder only to use it for basic applications, never fully exploring the range of possibilities this tool offers. The truth is that an extruder does far more than create simple clay strings. It serves as a pattern maker, a texture tool, a time-saving device, and an innovation catalyst that can elevate your work from amateur to professional quality. The key lies in understanding both fundamental techniques and creative applications that push beyond conventional uses.

This comprehensive guide explores over fifteen distinct ways to utilize your polymer clay extruder, from jewelry making to home decor, from beginner-friendly projects to advanced artistic applications. Each idea includes practical insights drawn from real-world experience, ensuring you can implement these techniques immediately in your own studio. By the end of this article, you will view your extruder not as a single-purpose tool but as a gateway to countless creative possibilities.

Understanding Your Polymer Clay Extruder

Before diving into specific projects, you need a solid grasp of how extruders function and what makes them effective. A polymer clay extruder consists of a barrel that holds conditioned clay, a plunger that applies pressure, and interchangeable discs that determine the shape of your extruded clay. The quality of your results depends on proper clay conditioning, consistent pressure application, and choosing appropriate disc shapes for your intended project.

Professional-grade extruders typically offer better leverage and durability compared to basic models. However, even entry-level extruders can produce excellent results when used correctly. The secret lies in conditioning your clay to the right consistency. Clay that is too firm will require excessive force and may produce uneven extrusions, while overly soft clay can create mushy, difficult-to-handle results.

Temperature also plays a crucial role in extruder performance. Working in a room that is too warm can soften your clay excessively, while cold conditions make extrusion unnecessarily difficult. Many experienced artists keep their clay at room temperature and warm it slightly through hand conditioning before loading it into the extruder barrel.

Creating Intricate Jewelry Components

Jewelry making represents one of the most popular applications for polymer clay extruders. The tool allows you to create perfectly uniform beads, connector pieces, and decorative elements that would be nearly impossible to replicate by hand. Start with simple round extrusions to create spacer beads, then progress to more complex shapes as your confidence grows.

For pendant designs, try extruding clay through triangular or square discs, then slicing these into segments and arranging them into geometric patterns. The uniformity of extruded pieces ensures your final design maintains visual balance and professional appearance. You can also create multi-colored extrusions by loading the barrel with marbled or striped clay, producing beads with built-in patterns that eliminate the need for surface decoration.

Earring components benefit tremendously from extruder use. Create matching pairs by extruding a single long piece, then cutting it into equal segments. This guarantees symmetry that hand-rolling simply cannot match. Experiment with twisted extrusions by gently rotating extruded strings while the clay is still warm and pliable, creating spiral effects that add visual interest to simple designs.

Designing Custom Picture Frames and Borders

Home decor projects gain tremendous character through extruded polymer clay embellishments. Picture frames transform from ordinary to extraordinary when you add custom borders made from extruded clay ropes and decorative elements. Begin by selecting a plain wooden or cardboard frame as your base, then plan your border design using paper sketches.

Extrude long ropes of clay in complementary colors, then twist or braid them together while still fresh from the extruder. Apply these braided borders directly to your frame using liquid polymer clay as an adhesive. The uniform thickness of extruded ropes ensures your border maintains consistent height and professional appearance all the way around the frame perimeter.

For more elaborate frames, combine multiple extrusion shapes into layered designs. Use small circular extrusions as decorative dots between larger rope borders, or create Greek key patterns by carefully arranging square extrusions at right angles. The possibilities expand exponentially when you start viewing extruded shapes as building blocks rather than finished elements.

Building Dimensional Wall Art

Wall art projects showcase the structural capabilities of polymer clay extruders in ways that surprise many artists. By extruding clay through larger diameter discs, you can create substantial architectural elements suitable for three-dimensional wall sculptures. These pieces add texture and depth that flat polymer clay work cannot achieve.

Consider creating abstract geometric wall installations by extruding multiple colors of clay, cutting them into various lengths, and arranging them into patterns on a backing board. The uniform diameter of extruded pieces creates visual rhythm and cohesion across your composition. Bake these arrangements directly on tile or parchment paper, then mount the finished piece on canvas or wood backing.

Nature-inspired wall art also benefits from extruder techniques. Create stylized trees by extruding brown clay for trunks and branches, then adding leaves made from flattened green extrusions. Underwater scenes come alive with extruded coral formations and seaweed strands. The key is planning your composition carefully before beginning extrusion, ensuring you have sufficient quantities of each color and shape.

Crafting Miniature Food and Dollhouse Accessories

Miniature artists have long recognized the extruder as an essential tool for creating realistic food items and dollhouse accessories. The precision and scale control offered by extruders make them ideal for projects requiring tiny, uniform components. Spaghetti, noodles, and other pasta shapes become remarkably simple when you extrude beige or yellow clay through fine circular discs.

For more complex food items, combine extrusion techniques with other polymer clay methods. Create realistic birthday cakes by stacking thin slices of extruded multi-colored clay, mimicking cake layers. Extrude green clay for lettuce shreds on miniature hamburgers, or create french fries by extruding rectangular shapes and adding subtle texture before baking.

Dollhouse furniture details also improve dramatically with extruder applications. Create uniform spindles for miniature railings by extruding clay through small circular discs. Fashion tiny curtain rods, picture frame moldings, and decorative trim work with precision that hand-rolling cannot duplicate.http://creative-polymer-clay-extruder-ideas The scale consistency across multiple pieces gives your miniature environments professional polish.

Developing Unique Cane Designs

Caning represents an advanced polymer clay technique that produces patterned logs which reveal intricate designs when sliced. Extruders accelerate and simplify certain caning methods, particularly those requiring numerous small, uniform components. Instead of hand-rolling dozens of tiny clay snakes for a complex millefiori cane, extrude them in seconds with perfect consistency.

Begin with simple bull’s-eye canes by extruding a core color, wrapping it with sheets of contrasting colors, then reducing the entire assembly. The extruded center maintains its circular shape throughout the reduction process, producing clean, professional results. Progress to more complex designs by arranging multiple extruded elements into patterns before reduction.

Checkerboard canes benefit enormously from extruder use. Extrude square logs in two contrasting colors, then arrange them in alternating patterns. The uniform size of extruded squares ensures your checkerboard pattern remains crisp and even when sliced. This technique saves hours compared to hand-cutting individual squares and produces superior results.

Constructing Holiday Ornaments and Decorations

Seasonal decorations gain special charm when crafted from polymer clay extrusions. Holiday ornaments benefit from the texture and dimension that extruded elements provide. Create candy cane ornaments by extruding red and white clay ropes, twisting them together, and forming them into traditional cane shapes. The uniform rope thickness ensures both colors remain visible in the final twist.

Snowflake ornaments showcase the geometric precision possible with extruder techniques. Extrude white or pearl clay through star-shaped discs, then arrange these extrusions into symmetrical snowflake patterns. Add crystal glitter or mica powder before baking to create shimmering surfaces that catch light beautifully. Attach hanging loops before baking for convenient ornament display.

Wreath decorations become more elaborate and professional with extruded embellishments. Create the wreath base from twisted green extrusions arranged in a circle, then add berries made from small red extrusions. Incorporate bows made from flattened ribbon-shaped extrusions in festive colors. The uniformity of extruded components gives these handmade decorations a polished, cohesive appearance.

Producing Textured Backgrounds and Surfaces

Texture creation represents an often-overlooked application for polymer clay extruders. By extruding clay directly onto flat sheets or background surfaces, you can create dimensional textures impossible to achieve through stamping or molding alone. This technique works exceptionally well for mixed media projects combining polymer clay with canvas, paper, or wood surfaces.

Experiment with extruding clay in random, overlapping patterns across a background sheet. Once baked, these textured surfaces can serve as focal points in larger artworks or as interesting backgrounds for jewelry components. Vary your pressure and angle as you extrude to create organic, flowing textures reminiscent of natural formations like tree bark or water ripples.

For more controlled texture patterns, plan your extrusion placement carefully. Create basket weave textures by laying horizontal extrusions, then weaving vertical pieces over and under them before baking.https://casolia.com/polymer-clay-extruder-ideas/ Develop brick or stone wall textures by arranging rectangular extrusions in staggered patterns. These textured sheets can be cut into shapes after baking or used as full background elements.

Making Custom Buttons and Closures

Functional items like buttons and closures gain personality when created with extruder techniques. Uniform button shapes ensure consistent sizing across a garment or project, while extruded decorative elements add visual interest. Begin with simple flat buttons by extruding thick discs, slicing them into rounds, and piercing holes for thread attachment before baking.

Shank buttons work equally well with extruder methods. Extrude a decorative top element, attach it to a simple base with liquid clay, and embed a commercial shank before baking. The extruded top can feature any disc shape available for your extruder, from flowers to stars to abstract geometric forms. This approach produces buttons far more interesting than plain commercial alternatives.

Toggle closures for jewelry and garments benefit from extruded construction. Create the toggle bar by extruding clay through a rectangular disc, then fashion the loop from a circular extrusion formed into a ring shape. These handmade closures add artisanal quality to any project while providing secure, functional fastening.

Designing Garden Stakes and Outdoor Markers

Outdoor applications for polymer clay expand significantly with extruder techniques, particularly for garden stakes and plant markers. While polymer clay itself is weather-resistant after baking, sealing your finished pieces with outdoor varnish ensures long-term durability. Create decorative toppers for garden stakes by arranging extruded elements into flowers, butterflies, or abstract designs.

Plant markers become both functional and decorative with extruded lettering and borders. Extrude thin ropes of clay and form them into letters spelling plant names, applying these to flat background pieces. Add decorative borders made from twisted extrusions or small circular dots arranged around the perimeter. The raised letters remain readable even after exposure to soil and water.

Garden stepping stones gain personality through extruded embellishments. While the main stepping stone body typically consists of concrete or larger clay sheets, adding extruded polymer clay decorations creates focal points and visual interest. Embed these decorations into the surface before the base material sets, ensuring permanent attachment.

Creating Educational Tools and Manipulatives

Teachers and parents discover that polymer clay extruders excel at producing educational materials and learning tools. The uniformity of extruded pieces makes them ideal for counting manipulatives, pattern recognition exercises, and hands-on math activities. Extrude rods in different colors, then cut them into equal lengths for fraction demonstrations or counting practice.

Alphabet and number learning benefits from three-dimensional extruded letters and numerals. Unlike flat printed materials, these tactile elements engage kinesthetic learners and provide sensory feedback that reinforces learning. Create complete alphabet sets by forming extruded ropes into letter shapes, baking them, and storing them in organized containers for repeated use.

Science models gain clarity through extruded construction techniques. Build molecular models using extruded spheres for atoms and thin extrusions for bonds. Create cross-section models of plant stems or geological formations by arranging colored extrusions in appropriate patterns. These durable, three-dimensional teaching aids withstand repeated handling far better than paper models.

Fashioning Hair Accessories and Adornments

Hair accessories transform from ordinary to artistic through thoughtful extruder applications. Barrettes gain dimension and interest when decorated with extruded flowers, geometric patterns, or abstract designs. Start with commercial barrette bases, then create your decorative elements by arranging extruded components into pleasing compositions before baking.

Hair sticks showcase the structural possibilities of polymer clay extrusions. Extrude decorative toppers featuring spirals, flowers, or beads, then attach them to wooden dowels or metal hair stick bases. The uniform components create balanced, symmetrical designs that look professional and polished. Seal finished pieces with glaze to protect them from hair products and handling.

Bobby pin decorations add subtle artistic touches to hairstyles. Create tiny flowers or geometric shapes from extruded elements, keeping them lightweight to avoid sliding. Attach these decorations to bobby pin bases using strong adhesive after baking. The small scale of these projects makes them perfect for using leftover clay scraps from larger extrusion sessions.

Assembling Mosaic Art Pieces

Mosaic techniques blend beautifully with polymer clay extrusion methods, creating artwork that combines traditional mosaic aesthetics with modern material flexibility. Instead of cutting individual tiles from clay sheets, extrude uniform logs and slice them into consistent tesserae. This approach dramatically reduces preparation time while ensuring visual consistency across your mosaic surface.

Create gradient effects in mosaic pieces by extruding multiple shades of a single color family, then arranging sliced pieces from light to dark. The uniform size of extruded tiles makes achieving smooth color transitions straightforward and predictable. Grout lines between tiles can be real grout mixed with acrylic paint, or you can eliminate grout entirely for a contemporary look.

Three-dimensional mosaic sculptures gain structural integrity from extruded foundations. Build armatures from aluminum foil or wire, then cover them with extruded clay elements arranged in mosaic patterns. This technique works particularly well for sculptural vessels, decorative spheres, or abstract art objects that combine form and surface pattern.

Inventing Games and Puzzle Pieces

Custom game pieces and puzzles become feasible projects with extruder assistance. Create uniform game tokens by extruding clay and slicing it into equal pieces, then decorating each piece differently to distinguish player pieces. The consistency of extruded components ensures fair gameplay by maintaining identical sizes across all tokens.

Puzzle construction benefits from extruded frameworks and decorative elements. Build jigsaw puzzle pieces by creating interlocking extruded shapes, or design three-dimensional puzzles where extruded rods fit into corresponding holes. Educational puzzles teaching shapes, colors, or patterns work particularly well with extruded components due to their durability and tactile nature.

Memory matching games gain visual appeal through extruded decorations. Create pairs of tiles featuring identical arrangements of extruded elements, ensuring each pair matches exactly. The three-dimensional nature of extruded decorations makes these games more engaging than flat printed alternatives, particularly for young children developing fine motor skills.

Developing Mixed Media Art Components

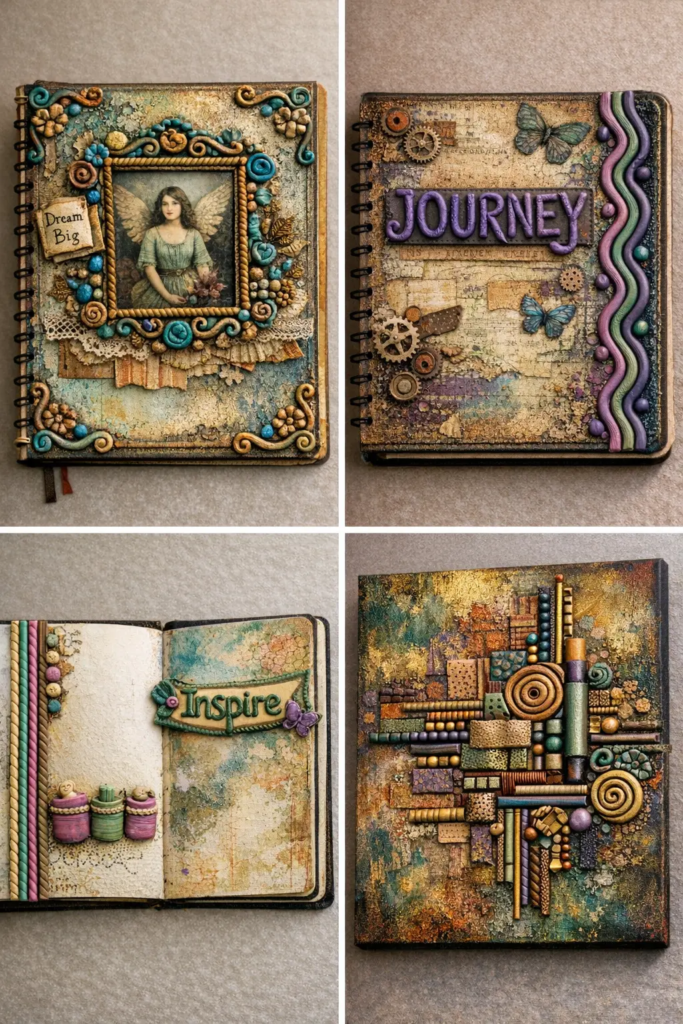

Mixed media artists find polymer clay extruders invaluable for creating dimensional elements that integrate into larger compositions. Unlike flat embellishments, extruded components add physical depth and shadow to mixed media pieces, creating visual interest and textural contrast. Incorporate extruded frames around focal images, or use extruded elements as three-dimensional journaling embellishments.

Art journal pages gain personality through extruded borders and decorative accents. Create custom dividers by extruding thin sheets in complementary colors, cutting them to size, and adhering them to page edges. Add dimensional titles by forming extruded ropes into letter shapes and attaching them to journal covers. These durable embellishments withstand repeated handling better than paper alternatives.

Canvas art projects expand beyond traditional painting when you incorporate extruded polymer clay elements. Build up surface texture by applying extruded pieces directly to primed canvas, creating relief surfaces that interact with paint and other media. This approach works exceptionally well for abstract art where texture and dimension contribute significantly to overall impact.

Constructing Bookmarks and Reading Accessories

Reading accessories become personalized art pieces through creative extruder applications. Bookmarks gain dimension and durability when topped with extruded decorative elements. Create bookmark bases from thin clay sheets or use commercial metal bookmarks as foundations, then add personality through arranged extruded components featuring flowers, geometric patterns, or themed designs.

Book thongs, which consist of decorative elements attached to ribbons that mark multiple pages simultaneously, showcase extruder versatility. Extrude beads in graduated sizes, string them onto ribbons, and finish with larger extruded focal beads. The uniform bead sizing ensures visual balance while the variety of disc shapes available provides endless design possibilities.

Reading lights and book stands gain decorative appeal through extruded embellishments. While the functional components remain metal or wood, adding polymer clay decorations personalizes these accessories and makes them gift-worthy. Create themed decorations matching book genres or reader interests, using extrusions to build up three-dimensional scenes or abstract patterns.

Conclusion

The polymer clay extruder represents far more than a simple tool for creating clay strings. As this exploration demonstrates, extruders open doors to countless creative applications spanning jewelry, home decor, educational materials, art projects, and functional items. The key to maximizing your extruder’s potential lies in viewing it not as a single-purpose device but as a versatile instrument capable of producing uniform components that serve as building blocks for larger creative visions.

Success with extruder techniques requires patience, proper clay conditioning, and willingness to experiment beyond obvious applications. Start with simpler projects that build your confidence and understanding of how different clay consistencies and disc shapes perform. As your skills develop, combine multiple techniques in single projects, layering simple extrusions into complex designs that showcase your growing expertise.

The investment in a quality extruder pays dividends throughout your polymer clay journey. Unlike tools with narrow applications, an extruder remains relevant whether you are creating simple beginner projects or advanced professional work. It saves time, ensures consistency, and enables techniques that would be prohibitively difficult or impossible by hand. Most importantly, it frees your creativity by eliminating technical barriers that might otherwise limit your artistic expression.

As you incorporate these fifteen ideas into your polymer clay practice, remember that each technique serves as a foundation for further innovation. The most exciting applications often emerge when you combine multiple approaches or adapt existing techniques to solve unique creative challenges. Your extruder stands ready to support whatever vision you pursue, transforming simple clay into extraordinary creations that reflect your personal artistic voice.

Frequently Asked Questions

What type of polymer clay works best in extruders?

Medium-firmness polymer clay brands like Premo and Fimo Professional perform most reliably in extruders. Avoid clay that is too soft as it produces mushy extrusions, and thoroughly condition firm clay before loading it into the barrel. Room temperature clay generally extrudes more smoothly than cold clay straight from storage.

How do I prevent air bubbles in extruded clay?

Condition your clay thoroughly before extruding, working out all air pockets through folding and rolling. Load the extruder barrel carefully, pressing clay firmly against the bottom and sides to eliminate gaps. Extrude slowly with steady pressure rather than quick, jerky movements that trap air.

Can I extrude multiple colors simultaneously?

Yes, loading the barrel with side-by-side colors or marbled clay creates multi-colored extrusions with built-in patterns. Experiment with different color placement arrangements to discover which combinations produce your desired effects. Clean the barrel between color changes to prevent unwanted mixing.

How long do extruded clay pieces stay workable?

Extruded clay remains workable for the same duration as any conditioned polymer clay, typically several hours at room temperature. Store unused extrusions wrapped in plastic wrap or wax paper to prevent dust accumulation. If extrusions become too firm, warm them slightly between your hands before continuing work.

What should I do if my extruder becomes difficult to operate?

Difficulty extruding usually indicates clay that is too firm, a barrel that needs cleaning, or worn components. Ensure your clay is properly conditioned, clean the barrel and plunger with baby wipes or rubbing alcohol, and check that all disc and barrel threads are clear of dried clay. Consider upgrading to a higher-quality extruder if mechanical issues persist.

2 Comments